Tungsten Oxide Oxygen Evolution

Tungsten oxide oxygen evolution is half reaction of tungsten oxide as photoelectric catalyst to decompose water, co-exist with hydrogen evolution to constitute the photolysis of water. Tungsten oxide (WO3), yellow tungsten oxide with band gap of 2.4~2.8eV, is a good performance of photocatalyst. Oxygen evolution reaction referred to OER, the process is generally accompanied with hydrogen evolution.

Numerous studies found that synthesizing and photocatalytic oxidative decomposition of water oxygen evolution performance of tungsten oxide which prepared by different materials and preparation methods has very close contact with structure. If tungsten oxide photocatalyst prepared from ammonium paratungstate (APT) as the raw material through solid phase and sintering method, it made up of monoclinic phase primarily; and experiments showed that when the process temperature is 600 ℃, the processing time of 4 hours, hexagonal phase oxidation tungsten appears with oxygen index of 2.44 and the highest rate oxygen evolution reaction water photolysis.

In addition, tungsten oxide produced by hydrothermal crystallization method from tungstic acid has the quadrature and hexagonal phase, the oxygen index is 2.50 and the photocatalytic water splitting performance has been greatly improved, wherein the product of 24 hours hydrothermal has the highest rate of oxygen evolution.

Microstructure determines photoelectric catalytic properties of tungsten trioxide films. Studies took tungsten sheet as raw material for oxidation treatment by the hydrothermal reaction, guided tungsten trioxide crystal growth by the crystal growth directing agent to form tungsten trioxide nano-film material. Experiments showed that this film has excellent performance in like large specific surface area and photoelectrocatalytic to help it showing huge superiority in oxygen evolution.

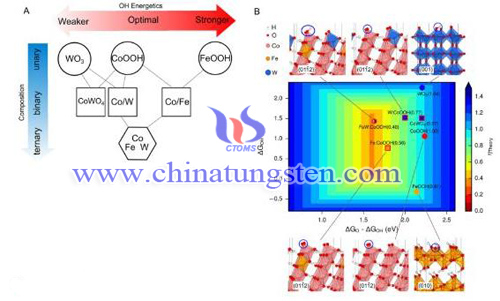

2016, the latest research indicated that gum Fe-Co-W-Oxyhydroxides multi-metal catalyst for oxygen evolution which produced by adding tungsten into cobalt iron oxide for regulating electronic structure of iron and cobalt, has the lowest oxygen evolution overpotential so far to achieve efficient water electrolysis oxygen evolution. This result has found a new direction for further optimizing oxygen evolution catalyst, and is expected to be widely used in fields of energy conversion and storage.

If you have any interest in tungsten oxide, please feel free to contact us by email: sales@chinatungsten.com or by telephone:+86 592 5129696.

More info>>