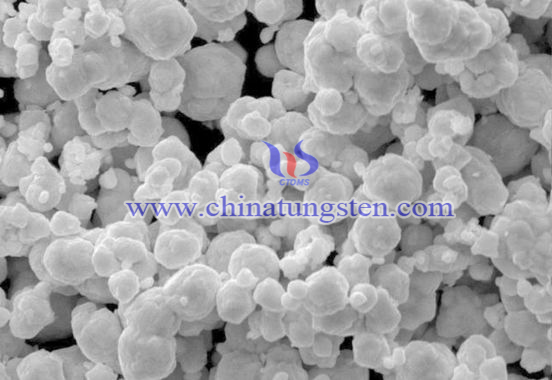

Nanometer Tungsten Carbide Powder

Product performance of nano tungsten carbide powder

1. Nanometer tungsten carbide powder, has high purity, particle size uniform dispersion of good, is an important raw material of producing cemented carbide, nano tungsten carbide powder can make hard alloy has many more excellent properties;

2. Nanometer tungsten carbide powder except has high hardness, hard king outside, still has wear resistance, corrosion resistance, temperature, etc;

3. The melting point was 2860°C±50°C, boiling point was 6000°C and also insoluble in water, strong acid resistance, high hardness and elastic modulus.

Why is nano tungsten carbide powder important?

Cemented carbide is the tooth of modern industry. Without cemented carbide cutting tools, there is no need to talk about modern industrial processing; high-end cemented carbide tool molds are the crown of the cemented carbide field. The production of such high-end cemented carbide, nano-tungsten carbide Flour is the necessary main raw material, not one of them. Gold tungsten carbide powder (WCP) is the main raw material for preparing cemented carbide. Its particle size determines the properties of cemented carbide. Under the same conditions of other materials and production processes, as the particle size of tungsten carbide decreases, the hardness, Both wear resistance and toughness are improved compared with conventional cemented carbide; especially when the particle size of tungsten carbide is reduced to nanometer level (< 100nm), its cemented carbide has high hardness and high strength properties. Therefore, the first condition to produce high-performance nano-tungsten carbide is to prepare high-quality nano-sized tungsten carbide powder.

What is the production process of nano tungsten carbide powder?

Taking the large-scale production equipment and process flow of Xiamen Jinlu Special Alloy Co., Ltd., which is currently recognized as the highest level of domestic tungsten powder and tungsten carbide powder production capacity and technology, as an example, the basic process flow of industrial production of nano-scale tungsten carbide powder is as follows:

Violet tungsten (WO2.72) is used as raw material, and gas phase migration is controlled by high-flow dry hydrogen reduction. After in-situ reduction to nano-tungsten powder with an average particle size of 30nm, nano-tungsten powder is used as raw material and granular carbon black is used as carbon source at 6.3%. The amount of carbon to be prepared is uniformly prepared by stirring ball milling for 1 hour, carbonized at 1300°C for 45 minutes under the protection of hydrogen, and the charge is dispersed by air flow dispersion equipment, and finally sifted to obtain nano-tungsten carbide powder. Nano tungsten carbide powder with good quality can be obtained by controlling the process parameters such as loading amount, carbon ratio, carbonization temperature, and carbonization time.

Other production and preparation processes of nano-tungsten carbide powder. The technology of preparing nano-tungsten carbide powder by plasma cooperative ball milling tungsten powder raw material activated carbonization method, the core is to introduce low-temperature plasma into the tungsten powder ball milling cavity, and at the same time of ball milling the tungsten powder, there is a plasma field in the ball milling cavity Through the joint action of plasma field and mechanical energy, the effect of mechanical alloying of tungsten powder is strengthened, especially the effect of activated tungsten powder is improved, and nano-tungsten carbide powder is synthesized by carbonization at a lower temperature. The dielectric barrier discharge plasma cooperative mechanical alloying technology mainly includes: the complex motion plasma discharge technology that satisfies the ball milling of tungsten powder in the ball mill cavity, the dielectric barrier discharge plasma power supply technology that meets the requirements of ball milling, the tungsten powder mechanical ball milling process and plasma Discharge parameters match the technology of synthesizing nano-tungsten carbide, etc.

Application of nanometer tungsten carbide powder

1.Nanometer tungsten carbide powder applied in composite materials, improve its performance: Nano-Tungsten carbide-cobalt (WC-Co) composite performance carbide powder preparation is the main raw materials and wear-resisting coating. Such as: cutting tools, computer, machinery, etc;

2. Nanometer tungsten carbide powder appropriate under high temperature on mechanical processing, can produce cutting tools, kiln of structural materials, the jet engines, gas turbines and nozzle, etc.

Storage conditionsThis product should be stored in dry, cool and sealing of the environment, can not be exposure to air, in addition should avoid the heavy pressure, according to ordinary goods transportation.

Nanometer Tungsten Carbide Powder Technical Parameters |

|||||

| APS(nm) | Purity(%) | Specific Surface Area(m2/g) | Volume Density(g/cm3) | Density(g/cm3) | Color |

| 80 | 99.9 | 60 | 3.2 | 15.5 | black, crystal form hexagon |

Note:according to user requirements of nano particle can provide different size products.

Packing: In sealde plastic bags with outer iron drums of 100/200 kgs net each. we can meet your special requirements.

If you have any interest in nanometer tungsten carbide powder, please feel free to contact us by email: sales@chinatungsten.com or by telephone: +86 592 5129696.

More info>>