What Are The Production Methods of Ultrafine Tungsten Carbide Powder?

Production Method of Ultrafine Tungsten Carbide Powder

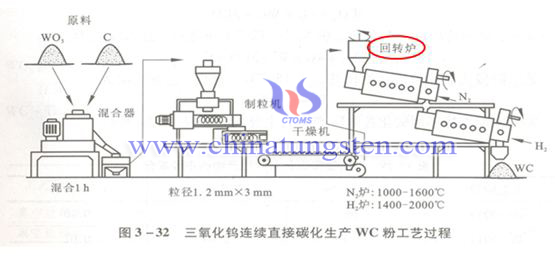

(1) Direct Carbonization of Tungsten Trioxide

Step 1, ultrafine grain nucleation occurs in the process of WO2.72 to WO2 transformation. The intermediate product WO2.72 is caused by its extremely fine grain size and the sharp volume shrinkage and significant increase in density during the transformation process from WO2.72 to WO2. When the material contains carbon black, volatile WO2 (OH) 2 hydrates that promote grain growth will not be formed.

Step 2: Ultrafine tungsten powder is directly carbonized into ultra-fine WC powder under 1597oC and H2 atmosphere.

Schematic diagram of typical continuous and direct production of tungsten carbide powder from tungsten trioxide used by Tokyo Tungsten and Sumitomo Electric Co., Ltd. in Japan

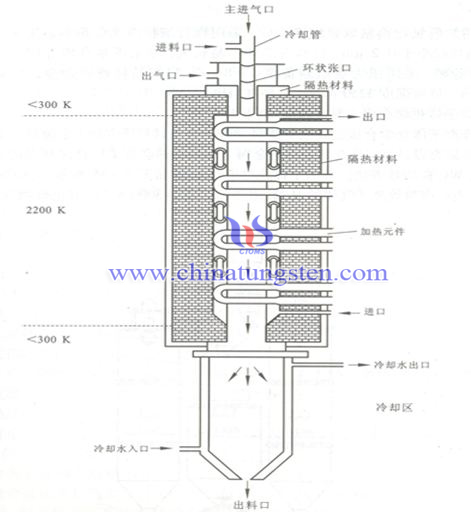

(2) Rapid Carbothermal Reduction Carbonization

Firstly, tungsten oxide and carbon black are carried out in a continuous vertical reactor. Ar gas with certain pressure entrains the raw material mixture into the reaction zone in the form of fog. The mixture reaches its peak heat at a speed of 104~108K per second; Secondly, after the reactant leaves the high temperature zone, the flowing Ar gas will bring the product into the stainless steel water cooling zone to rapidly cool it to below 283K, and then further carbonization treatment will be carried out.

Process diagram of tungsten carbide powder production by rapid carbothermal reduction carbonization method of Dow Chemical Company

(3) Production of ultrafine tungsten carbide powder from purple tungsten oxide

Ultrafine tungsten carbide powder produced from purple tungsten oxide is characterized by that purple tungsten oxide (WO2.72) is a loose and porous thin polymer, which is conducive to H2 infiltration and water vapor overflow during reduction. On this basis, ultra-fine WC powder is further produced.

(4) Ultrafine/nano WC powder was prepared by plasma chemical synthesis.

(5) Nano WC powder was prepared by displacement reaction.

(6) Nano WC powder was prepared by mechanical alloying.

(7) Nano WC powder was prepared by mechanochemical synthesis.

If you have any interest in tungsten carbide powder, please feel free to contact us by email: sales@chinatungsten.com or by telephone: +86 592 5129696.

More info>>

1.Cast Tungsten Carbide Powder

2.Fine Tungsten Carbide Powder

3.MSDS of Tungsten Carbide Powder-1

4.MSDS of Tungsten Carbide Powder-2