Crystalline Tungsten Carbide Powder

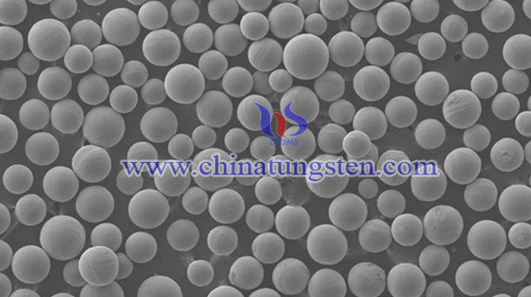

Crystalline tungsten carbide powder, also known as spherical tungsten carbide powder, is also called tungsten carbide crystal powder for spraying according to its use.

The appearance of crystalline tungsten carbide is steel gray powder with good fluidity. High purity, uniform particle size, good dispersion, insoluble in cold water, strong acid resistance, high hardness, large elastic modulus. In addition to high hardness, tungsten carbide also has the characteristics of wear resistance, corrosion resistance and high temperature resistance. Crystalline tungsten carbide is an important raw material for the production of cemented carbide. Nano tungsten carbide powder can make cemented carbide have many more excellent properties. It is mainly composed of refractory metal tungsten and non-metallic carbon, and contains a small amount of impurity elements such as Co and Cr. , Ti, Ta, Nb, V, Mn, Ni, Mo, O, etc. According to the particle size, it can be divided into the following grades, WC10 (1.01~1.40um), WC30 (3.01~4.00um), WC50 (5.01~7.00um), WC100 (10.01~14.00um), etc.

What are the characteristics of crystalline tungsten carbide powder and spherical tungsten carbide powder?

Appearance is black powder, high purity ≥ 99.9%, sphericity ≥ 95%, melting point 2870 ℃, boiling point 6000 ℃, density 15.63g/cm³, bulk density greater than 7.0g/cm3, tap density greater than 7. 5g/cm3, the flow property is less than 10.0s/50g, it has the characteristics of high hardness, low thermal expansion coefficient, high compressive strength, large elastic modulus, and smooth surface. However, due to its high hardness, its processing performance is poor, so it is more suitable for 3D printing.

Production process of crystalline tungsten carbide powder and spherical tungsten carbide powder

1) Melting method: The raw material powder (tungsten powder and carbon black or tungsten powder, carbon black and tungsten carbide) is melted into a liquid state, and the droplets will be in the centrifugal rotation method, rotary atomization method or gas atomization method. Spherical tungsten carbide is formed on the surface.

2) Modification of tungsten carbide with irregular shape: Melt WC with irregular shape into a liquid state, and then use plasma spheroidization method or resistive heating spheroidization method to make spherical tungsten carbide powder.

Application of crystalline tungsten carbide powder and spherical tungsten carbide powder

Crystalline tungsten carbide is expected to be used in all kinds of cemented carbide and diamond drill raw materials for oil drilling; plasma transferred arc surfacing (PTA), laser cladding, thermal spraying and other production.

Crystallized tungsten carbide packaging storage

Keep sealed in a dry, cool environment, and should not be exposed to the air for a long time.

If you have any interest in tungsten carbide powder, please feel free to contact us by email: sales@chinatungsten.com or by telephone: +86 592 5129696.

More info>>

1.Cast Tungsten Carbide Powder

2.Fine Tungsten Carbide Powder

3.MSDS of Tungsten Carbide Powder-1

4.MSDS of Tungsten Carbide Powder-2