Preparation Method of 3D Printing Spherical Powder

The preparation method of 3D printing spherical powder can be divided into reduction method, electrolysis method, grinding method, atomization method, etc. according to the preparation process. At present, the two most advanced pulverizing processes commonly used in China are argon atomization method and plasma rotating electrode method.

1. Argon Atomization

Argon atomization powder making is a method of making powder by using fast flowing argon gas to impact metal liquid, breaking it into fine particles, and then condensing it into solid powder.

2. Plasma Rotating Electrode Method

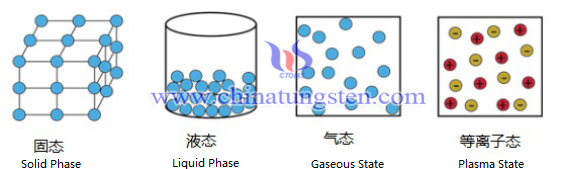

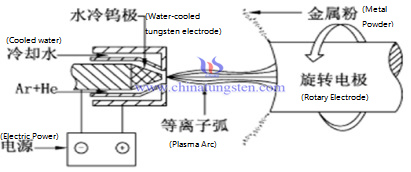

The plasma state is called the fourth state of matter. The process of powder preparation by plasma rotating electrode atomization (PREP method) can be simply described as: metal or alloy is made into consumable electrode, the end of consumable electrode is melted to form a liquid film under the action of coaxial plasma arc heating source, the liquid film is thrown out at high speed under the action of rotating centrifugal force to form droplets, and the molten droplets rub with inert gas (argon or helium) in the atomization chamber, Under the action of shear stress, the droplets are further broken, and then rapidly cooled and solidified into spherical powder under the action of surface tension.

The metal powder produced by the plasma rotating electrode method has the following advantages:

(Schematic diagram of plasma rotating electrode atomization method)

The sphericity is high, the surface is smooth and clean, the fluidity is good, and the loose packing density is high, so the powder spreading uniformity is good, and the density of printed products is high; The powder has small particle size, narrow particle size distribution, low oxygen content, little/no spheroidization and agglomeration during printing, good melting effect, high product surface finish, and the consistency and uniformity of printing can be fully guaranteed; There is basically no hollow powder, satellite powder, air gap, entrapment and precipitation porosity, cracks and other defects caused by the hollow ball in the printing process.

If you have any interest in spherical tungsten powder, please feel free to contact us by email: sales@chinatungsten.com or by telephone: +86 592 5129696.

More info>>