Tungsten Sulfide

Introduction

Name: Tungsten Disulfide

Other Names: Tungsten Sulfide; Bis(Sulfanylidene)Tungsten; Tungsten Sulfide; Tungsten(iv) Sulfide;

CAS: 12138-09-9

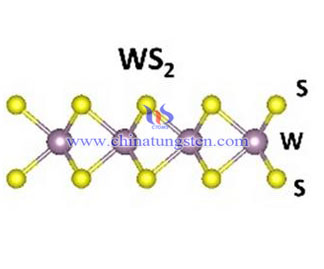

Formula: S2W

Molecular weight:247.97000

Exact Mass:247.89500

Property

Tungsten disulfide appears in gray, hexagonal, with semiconducting and anti-magnetic. Tungsten disulfide has layered structure, which is easy to dissociate and with lubricating properties similar to graphite, which makes it a lubricant, such as being an aerosol. Its melting point is 1480ºC.

Tungsten disulfide can slightly soluble in water, soluble in hot water, but will not not dissolve in hydrochloric acid and alkali; besides, it can dissolve in molten alkali, but insoluble in alcohol. The density of tungsten disulfide is 7.6g•cm-3. Also, tungsten disulfide has reducing property, and can react with strong oxidizing agent such as hot concentrated sulfuric acid, nitric acid, aqua regia; furthermore, it may be converted to WO3 when heated in air or oxygen.

Preparation

Take the tetrathiocarbonate ammonium tungstate as raw material and put them in the absence of air, heated at the rate of 100~200℃/hr from room temperature to 700~1200℃ to decompose the material, and maintain this temperature for 24~48 hours, then lowered the temperature at the rate of 30~110℃/hour down to room temperature, pulverizing the material.

Industrial Use

Tungsten disulfide can be used as a lubricant and performance better than molybdenum disulfide with the low coefficient of friction and greater compressive strength. It can be alone used in the conditions of high temperature, pressure, speed, load, as well as in the running device with chemically active medium. Filler formulated by tungsten disulfide, PTFE and nylon can be used for making self-lubricating components.

In addition, tungsten disulfide may also be used as catalysts in the petrochemical industry, and the advantages are high-performance in cracking, stable and reliable catalytic activity, long service life.

Industrial Use

1. Tungsten disulfide has a very low coefficient of friction (0.03), high resistance to extreme pressure and oxidation resistance (It begins to be decomposed in air at 450℃ and completely decomposed at 650℃; when in the vacuum, it begins to be decomposed at 1100℃ and completely decomposed at 2000℃ ). Tungsten disulfide is very suitable used as a lubricant in the harsh conditions like high temperature, pressure, vacuum, load, speed and radiation, strong corrosion, extremely low temperatures.

2.Tungsten disulfide has a good adsorption capacity for the metal surface. You can add lubrication made in the original plastic or mixed with certain volatile solvents even after spraying the metal surface to improve life in the forging punch and die surface finish.

Tungsten disulfide powder with oil, fat oil can formulate to tungsten disulfide oil, grease, wax and other tungsten disulfide solid lubricating block or lubricating film.