Tungsten Oxide Nanotube

When particle size of some material reaches to nano grade (1~100nm), it can show many special reactions. It can be widely applied in functional information display, catalyst, magnetic material. Among which, tungsten oxide has various crystalline structure, it has a large amount of non-stoichiometry oxide form and has multi-functional broad-band gap semiconductor material. WO3 is widely applied in gas sensor, photocatalyst, gasochromism, electrochromism, photochromism and solar cell due to its unique electricity, optical configuation, and magnetic property. Apart from that, temperature induces structure phase transition which results in the changes of volume, resistance and color greatly draw people’s attention. The research on its special structure has become the focus of recent study.

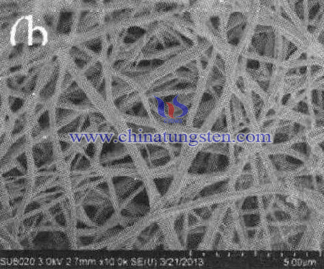

The traditional preparing method of tungsten oxide nanotube need extra coating and sculpture process, the quality of nanotube greatly depends on the control of processing steps. By coaxial electrospinning, hollow nano fiber can be obtained, manufacturing process is simplified.

Raw material: PVA; ammonium metatungstate; absolute ethyl alcohol; aluminum foil; deionized water.

Preparing process:

(1) Weigh a certain amount of PVA to dissolve in deionized water, stirring it for 4hous in constant temperature of 80℃ and prepare it to 15% PVA solution. Then add 24ml alcohol and 6g ammonium metatungstate solution into 60ml PVA solution.

(2) Dilute another 15% PVA solution to 10% as inner pipe solution by deionized water. Inject both inner and outer pipe solution into injector, then inject them into electrostatic spinning coaxial needle.

(3) Under electric voltage 9~15kV, keep spinning with receiving distance of aluminum foil for 10~12cm. Dry the obtained composite fiber in thermotank for 12 hours, keep the temperature to 600℃ by putting it in muffle furnace, and then cool it down to get WO3 nanotube.