Tungsten Powder Ceramic Rod Flame Spraying

Photo courtesy of Westaim Ambeon

Photo courtesy of Westaim Ambeon

ceramic rod flame spraying, a spraying process in which material to be sprayed is in ceramic rod form.

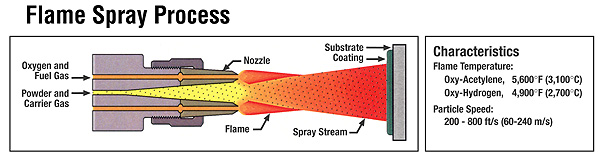

The spraying of ceramic rods dates back to the early 1950's when a demand arose for heat resistant refractory coatings. Plasma had not come into its own and flame sprayed powder coatings, due to their porous nature, lacked the integrity and protection required. The solution was rather simple - Coors Ceramic and Norton developed ceramic rods, referred to as Rokide, while the Metallizing Engineering Company (Mogul), modified a wire gun to spray rods. What differentiated the guns were the drive rolls. A wire gun had serrated steel rolls to grip and feed the wire while the Rokide gun employed "V" slotted fiber rolls that pinched the rods and fed them forward. The principle of operation in either gun is similar - the nozzle's flame is concentric to the wire or rod in order to maximize uniform heating. In the graphic below, a coaxial sheath of compressed gas around the flame atomizes the molten material and accelerates it to the workpiece. Particle velocities in both the wire and rod process are approximately the same - 185 m/sec (600 ft/sec) while coating densities have been measured at approximately 95 v/o.

Ceramic rods are 61 cm (24 in.) in length and offered in three diameters 1/8, 3/16 and 1/4 in. Compositions include several stabilized zirconias, white and gray alumina, and a spinel.

If you have any interest in our products, please feel free to contact us by email: sales@chinatungsten.com or by telephone: +86 592 5129696.

More info>>