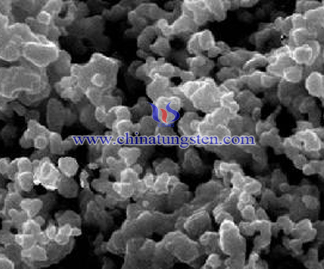

Fine Tungsten Carbide Powder

Introduction

A process is provided for producing a fine tungsten carbide powder, which comprises the steps of drying a slurry, which is obtained by mixing an aqueous ammonium tungstate solution with a carbon powder, at low temperature, to form a precursor, mixing a reduction and carburization product, which is obtained by reducing and oxidizing the precursor in an inert gas, with a carbon powder in a proportion required to substantially carburize the entire tungsten component into tungsten carbide(WC), and carburizing the mixture; and a high-performance fine tungsten carbide powder produced by the process, which has an average particle size of 0.8 μm or less and is free of a coarse powder having a particle size of more than 1 μm, and which also contains less metal impurities and contains oxygen and nitrogen in a predetermined amount.

| Mark | Particle Size(μm) | Chemical Composition (%) | ||||||

| T.C | F.C | C.C | Fe | Mo | Cr | V | ||

| WC-F(C) | 0.45〜0.75 | 6.08〜6.25 | ≦0.10 | ≧6.05 | ≦0.050 | ≦0.020 | ≦1.00 | - |

| WC-F(V) | 0.45〜0.75 | 6.08〜6.25 | ≦0.10 | ≧6.05 | ≦0.050 | ≦0.020 | - | ≦1.00 |

| WC-F(CV) | 0.45〜0.75 | 6.08〜6.25 | ≦0.10 | ≧6.05 | ≦0.050 | ≦0.020 | ≦1.00 | ≦1.00 |

| WC-F(N) | 0.45〜0.75 | 6.05〜6.22 | ≦0.10 | ≧6.05 | ≦0.050 | ≦0.020 | - | - |

Packing: In sealde plastic bags with outer iron drums of 100/200 kgs net each. we can meet your special requirements.