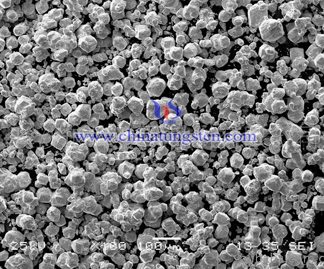

Coarse Tungsten Powder

Introduction

Coarse Tungsten Powder is primarily intended for applications utilizing non-thermal powder consolidation technologies (tungsten– polymer/elastomer, deformable metal binder, etc.) Special powder processing services available for narrow distribution, increased apparent density, and/or high flowability Provides coarse particle size with low alkali metal content-ideal for thermal spray. Widely used for lead-free ammunition and moldable radiation shielding products. Useful as a pour-in high density filling material for irregular shaped cavities to add weight or radiation attenuation.

TYPICAL PHYSICAL PROPERTIES OF COARSE TUNGSTEN POWDER

Type |

Avg. Particle Size FSSS (microns) |

Apparent Density(g/in3) |

Standard Screening |

C40 |

10.00-19.99 |

60 - 100 |

-100 Mesh |

C60 |

20.00-39.99 |

70 - 120 |

-60 Mesh |

C80 |

>40.00 |

90 - 130 |

-60 Mesh |

Typical Trace Element Chemical Analysis

METALLIC IMPURITIES (WT%) |

||||||

Element |

Max |

Typical |

Element |

Max |

Typical |

|

Al |

0.003 |

<0.001 |

Mo |

0.020 |

0.005 |

|

Co |

0.005 |

<0.001 |

Na |

0.010 |

0.005 |

|

Cr |

0.020 |

0.005 |

Ni |

0.020 |

0.005 |

|

Cu |

0.005 |

<0.001 |

Si |

0.002 |

<0.001 |

|

Fe |

0.020 |

0.002 |

Sn |

0.002 |

<0.001 |

|

NON-METALLIC IMPURITIES (WT%) |

||||||

Type |

Carbon |

Oxygen (Loss on Reduction) |

||||

C40 |

<0.008 |

<0.070 |

||||

C60 |

<0.008 |

<0.070 |

||||

C80 |

<0.008 |

<0.070 |

||||

TUNGSTEN (WT%) > 99.8% Excluding Gases |

||||||

ANALYTICAL REPORTS

A Certificate of Analysis (COA) accompanies each shipment of tungsten carbide powder. We prepare each COA to include the following: Average Particle Size (Fisher Sub-Sieve ASTM B-330) Apparent Density (Scott Volumeter ASTM B-329) Particle Size Distribution (Photelometer ASTM B-430, Sedigraph, or Malvern Mastersizer) Chemical Impurity Analysis Packing:In iron drums lined with double plastic bags of 50 or 100 kgs net each. Note: Any particular requirements to the products can be discussed.