Nano Cesium Tungsten Bronze

Introduction

A large number of transparent materials like glass, plastic are used in modern building, while these materials can improve indoor lighting, they will also lead to the sun light going into the room thus cause indoor temperature rising. In summer, people often use air conditioning to cool down the room temperature, this is the main reason for powder cutting in the summer in China. With the growing popularity of automobiles, the insulation film has become the standard configuration of a car for cooling down temperature inside the car.

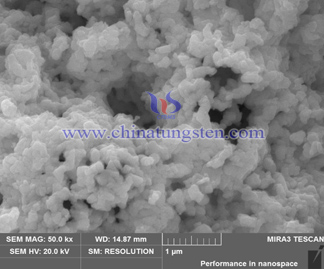

Nowadays the most effective way is adding nano particles which has near infrared ability into resin such as ATO, ITO and nano cesium tungsten bronze powder to preparing transparent heat insulating coating which can be coated on glass or Havelock, or coated on PET thin film in advance, then sticking it on the glass. It can also be made into plastic thin film, like PVB, EVA plastic, then recombine it with tempered glass to resist infrared ray. Among these nano particles, cesium tungsten bronze has the best near infrared shielding property. Usually adding 2g into per square meter of glass can reach transmittance less than 10% at 950nm(absorbance for near infrared ray). At the same time, at 550nm can reach transmittance more than 70%(70% refers to the index of mostly high transparent thin film).

Preparation

Solvent hot liquid phase method preparing nano cesium tungsten bronze:

1. Heating and dissolving 400kgs sorbitol in jacket reactor, adding tungstic acid and cesium sulfide, its mass ratio is 1:0.33. Mass of sorbitol is three times more than total weight of tungstic acid and cesium sulfide.

2. Stirring 30min under high speed, homogenate it into homogenizer, after 60min, adding the obtained material into autoclave which is heated to 150℃. Set the rolling rate of autoclave to 180r/min, after the above material is totally converted into autoclave, turn off the valves of it and heating it to 350℃, stay it warm for 600min, then lowering the temperature to 150℃.

3. Adding deionized water into reaction material, put them into press leaching machine, washing them with deionized water and absolute ethyl alcohol until sulfate radical content less than 100mg/kg, ethyl alcohol content more than 80%.

4. Dry the leaching material in vacuum drying machine, then processing mechanical pulverization and jet mill, the dark blue cesium tungsten bronze nano powder is obtained.

Cesium tungsten bronze nano sizing agent and transparent heating insulating coating preparation method:

1. Adding cesium tungsten bronze nano powder, deionized water, dispersant, sodium hydroxide or nitric acid into stirred tank, after stirring, put them into sander and then grind them to disperse. Until the particle size of sizing agent stays stable, stop grinding, the cesium tungsten bronze nano sizing agent is obtained.

2. Adding the sizing agent into acrylic emulsion, coating it on the glass substrate, then dry it to get the thin film of 5um, the adding amount is 1.3g/m2.

Property

Using xenon lamp to keep radiate the cesium tungsten bronze transparent heat insulating thin film, after 72hous, its appearance didn’t change obviously, it proves that cesium tungsten bronze nano powder has good resistance. The mechanism for it to shield infrared ray is the absorbance of infrared ray by oxygen valance in the nano powder. Oxygen valance would react with moisture in the air to lower its concentration, so the insulating effect is lower down, Soaking the insulating thin film in 60℃ hot water for 168hours, the shielding rate only drops for 1.8%, it shows the cesium tungsten bronze nano powder has better moisture resistance. The service life is approximately 20 years which can largely lower the cost of thin film.