|

Photo courtesy of Westaim Ambeon Photo courtesy of Westaim Ambeon

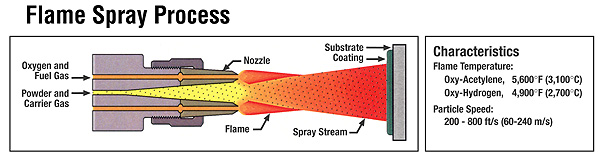

It has long been recognized that fluids may be broken up into very fine particles by a stream of high velocity gas emanating from a nozzle. Early experiments using this atomizing approach appear to have been directed at producing metallic powders rather than coatings. It was left to Schoop to appreciate the possibility that a stream of metallic particles, formed from a molten source, could produce a coating. Myth has it that Schoop developed the concept when playing "soldiers" with his son and observing the deformation of lead pellets being fired from a toy cannon against a brick wall. Whatever the rationale, it can be stated that the pioneer work of Schoop resulted in the discovery and development of metal spraying and subsequently the "Thermal Spray Process".

The first spray technique developed by Schoop was the outcome of experiments in which molten metal was poured into a stream of high velocity gases. Schoop's apparatus consisted of a compressor supplying air to a heated helical tube. The heated air was used to pressurize a crucible filled with molten metal and eject it out as a fine spray that would adhere to a suitable surface. This system was bulky, primitive and inefficient; however, the concept did lead to the development of portable and user friendly equipment.

There are no further accounts of molten metal spraying by Schoop, it appears that his efforts were directed at developing and improving powder and wire flame spraying. However, work by others continued as a 1924 Dutch patent, describing equipment for spraying low melting point metals, was granted to Jung and Versteeg (2). Mellowes Ltd commercialized the process in the UK. Their system consisted of a gun, a furnace, an air compressor and a fuel supply. The gun had many air and gas valves, a heating chamber (burner), nozzle, handle and a melting pot. The pot was bulky having the ability to store 1.8 kg (4 lb) of molten lead. The pot sat atop the heating chamber, which was similar in construction to a Bunsen burner. Compressed air, fed to the burner, intensified the flame. The handle jutted out and downward from the pot; it was insulated using wood and asbestos. Metal exited the pot through a front orifice where it was directed into a nozzle. Compressed air surrounded the nozzle, atomizing the molten metal and propelling it to the surface to be coated.

The molten metal process has advantages and disadvantages. Advantages include: cheap raw materials; use of inexpensive gases; and, gun design is very basic. Noteworthy disadvantages are: gun is cumbersome to use in the manual mode, can only be held in a horizontal plane; high maintenance due to high temperature oxidation and molten metal corrosion; and, useful only with low melting temperature metals.

Uses for the molten metal thermal spray process include the fabrication of molds, masks and forms for the plastics industry, using low melting point bismuth based alloys (the Cerro family of alloys); the deposition of solder alloys to joints that would be coalesced using torches or ovens; and, the production of metal powders.

0% of 0 voters found this FAQ useful, I found this FAQ useful useful not useful not useful

If you have any interest in our products, please feel free to contact us by email: sales@chinatungsten.com or by telephone:

+86 592 5129696.

More info>>

1.Tungsten Powder

2.Catalog of Tungsten Powder

3.E-catalog of Tungsten Powder

4.High Velocity Oxyfuel Spraying

|