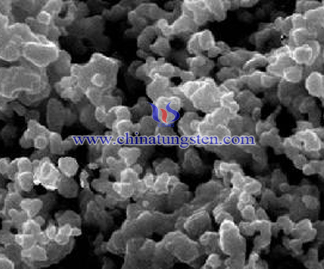

Bereit Wolframpulver zu Presse

Bereit Wolframpulver zu Presse

Klasse |

ISO Klasse |

Chemische Zusammensetzung(% in weight) |

||||||

|

|

WC |

Co |

TiC |

TaC |

other |

T.C |

Lubricant |

CTF40D |

- |

88.0 |

12.0 |

- |

- |

- |

5.32 |

2.0%wax |

CTD20A |

- |

91.0 |

9.0 |

- |

- |

- |

5.56 |

2.0%PEG |

CTT20A |

P20 |

79.3 |

8.0 |

8.7 |

4.0 |

- |

6.82 |

2.0%wax |

CTK10F |

K10 |

93.3 |

6.5 |

- |

- |

0.20 |

5.76 |

2.0%wax |

CTK30F |

K30 |

91.1 |

8.5 |

- |

- |

0.4 |

5.63 |

2.0%wax |

CTK50 |

K50 |

90.0 |

10.0 |

- |

- |

- |

5.52 |

2.0%wax |

CTF05 |

K02 |

97.0 |

3.0 |

- |

- |

- |

5.98 |

2.0%wax |

CTD22 |

- |

90.8 |

9.2 |

- |

- |

- |

5.55 |

2.0%wax |

CTU15F |

K10-K30 |

91.4 |

8.0 |

- |

- |

0.6 |

5.76 |

2.0%wax |

CTU25UF |

K10-K50 |

86.0 |

12.0 |

- |

- |

1.4 |

5.49 |

2.0%wax |

CTU10 |

K10 |

93.85 |

6.0 |

- |

- |

0.15 |

5.84 |

2.0%wax |

CTU20 |

K10-K20 |

89.5 |

10.0 |

- |

- |

0.5 |

5.57 |

2.0%wax |

CTU30 |

K20-K30 |

85.7 |

13.5 |

- |

- |

0.8 |

5.38 |

2.0%wax |

CTK02 |

K01 |

95.9 |

4.0 |

- |

- |

0.1 |

5.92 |

2.0%wax |

CTK05 |

K05 |

94.0 |

6.0 |

- |

- |

- |

5.79 |

2.0%wax |

CTK10 |

K10 |

94.0 |

6.0 |

- |

- |

- |

5.78 |

2.0%wax |

CTK20 |

K20 |

94.0 |

6.0 |

- |

- |

- |

5.79 |

2.0%wax |

CTK30 |

K30 |

92.0 |

8.0 |

- |

- |

- |

5.64 |

2.0%wax |

CTK40 |

K40 |

91.0 |

9.0 |

- |

- |

- |

5.57 |

2.0%wax |

CTF20D |

- |

94.0 |

6.0 |

- |

- |

- |

5.76 |

2.0%wax |

CTF25D |

- |

92.0 |

8.0 |

- |

- |

- |

5.63 |

2.0%wax |

CTF31 |

- |

90.5 |

9.5 |

- |

- |

- |

5.59 |

2.0%wax |

CTF40 |

- |

88.0 |

12.0 |

- |

- |

- |

5.40 |

2.0%wax |

CTF45 |

- |

87.0 |

13.0 |

- |

- |

- |

5.34 |

2.0%wax |

CTF50 |

- |

85.0 |

15.0 |

- |

- |

- |

5.20 |

2.0%wax |

CTF60 |

- |

80.0 |

20.0 |

- |

- |

- |

4.91 |

2.0%wax |

CTF65 |

- |

78.0 |

22.0 |

- |

- |

- |

4.78 |

2.0%wax |

CTF70 |

- |

75.0 |

25.0 |

- |

- |

- |

4.60 |

2.0%wax |

CTD10 |

- |

94.0 |

6.0 |

- |

- |

- |

5.77 |

2.0%wax |

CTD20 |

- |

92.0 |

8.0 |

- |

- |

- |

5.64 |

2.0%wax |

CTD25A |

- |

90.0 |

10.0 |

- |

- |

- |

5.51 |

2.0%wax |

CTD50 |

- |

85.0 |

15.0 |

- |

- |

- |

5.20 |

2.0%wax |

CTT20 |

P20 |

72.0 |

8.0 |

8.0 |

12.0 |

- |

6.86 |

2.0%wax |

CTT30 |

P30 |

75.8 |

8.0 |

6.2 |

10.0 |

- |

6.60 |

2.0%wax |

Pulvereigenschaften |

Physikalische Eigenschaften wie gesintertes |

||||

Durchschnittlich |

Ersichtlich density g/cm3 |

Fließen |

Härte HRA±0.5 |

Dichte |

TRS |

6.0 |

3.20 |

27 |

87.5 |

14.30 |

2800 |

8.0 |

3.70 |

25 |

86.5 |

14.60 |

2500 |

2.0 |

2.70 |

30 |

91.8 |

12.40 |

2200 |

1.8 |

3.40 |

27 |

92.0 |

14.86 |

3200 |

1.8 |

3.10 |

29 |

91.0 |

14.65 |

2800 |

1.8 |

3.20 |

28 |

90.5 |

14.54 |

2800 |

4.0 |

3.35 |

25 |

92.0 |

15.25 |

2100 |

4.0 |

3.20 |

28 |

88.4 |

14.62 |

2600 |

0.6 |

3.00 |

28 |

93.0 |

14.65 |

4200 |

0.4 |

2.70 |

30 |

93.0 |

14.10 |

4000 |

0.8 |

3.05 |

27 |

93.0 |

14.85 |

2700 |

0.8 |

2.85 |

30 |

91.8 |

14.45 |

3400 |

0.8 |

2.70 |

32 |

90.5 |

14.00 |

3500 |

1.3 |

3.40 |

24 |

92.7 |

15.15 |

2100 |

1.5 |

3.40 |

24 |

92.0 |

14.90 |

2450 |

2.0 |

3.40 |

26 |

91.5 |

14.90 |

2500 |

3.0 |

3.40 |

27 |

91.0 |

14.90 |

2600 |

3.0 |

3.35 |

28 |

90.0 |

14.70 |

2700 |

3.0 |

3.20 |

29 |

89.5 |

14.60 |

2800 |

4.0 |

3.40 |

26 |

90.0 |

14.90 |

2600 |

5.0 |

3.40 |

26 |

89.5 |

14.70 |

2800 |

4.0 |

3.30 |

26 |

89 |

14.43 |

2800 |

2.0 |

3.10 |

27 |

89.0 |

14.40 |

3000 |

2.5 |

3.05 |

30 |

88.5 |

14.20 |

3100 |

3.5 |

2.90 |

30 |

87.5 |

14.00 |

3000 |

5.5 |

2.75 |

32 |

84.5 |

13.65 |

2700 |

5.5 |

2.70 |

33 |

84.0 |

13.40 |

2700 |

5.5 |

2.65 |

33 |

82.5 |

13.18 |

2400 |

8.0 |

3.40 |

26 |

89.0 |

14.95 |

2500 |

8.0 |

3.40 |

26 |

86.5 |

14.60 |

2500 |

3.0 |

3.30 |

26 |

88.5 |

14.50 |

2850 |

6.0 |

3.20 |

27 |

86.0 |

14.00 |

3000 |

2.0 |

2.70 |

30 |

92.2 |

12.40 |

1900 |

2.0 |

2.80 |

28 |

91.5 |

12.80 |

2100 |

Chinatungsten Online produziert verschiedene Arten von pressfertiges Pulver, die weit verbreitet in der Herstellung von zementierten carbide.The Produkte haben die folgenden Eigenschaften verwendet: 1, stabil scheinbare Dichte 2, ausgezeichnete Fließfähigkeit durch sphärisches Aspekt des Pulvers 3, gute Kompressibilität 4, Hoch chemische Reinheit, gut Kontrolle der Kohlenstoffgehalt 5, Das Hartmetall hergestellt unserer RTP hat ausgezeichnete physikalische Eigenschaften

Verpackung: In sealde Plastiktüten mit äußeren Eisentrommeln von 100/200 kg netto je. wir können Ihren speziellen Anforderungen entsprechen.